U.S. Digital Textile Printing Market Developments

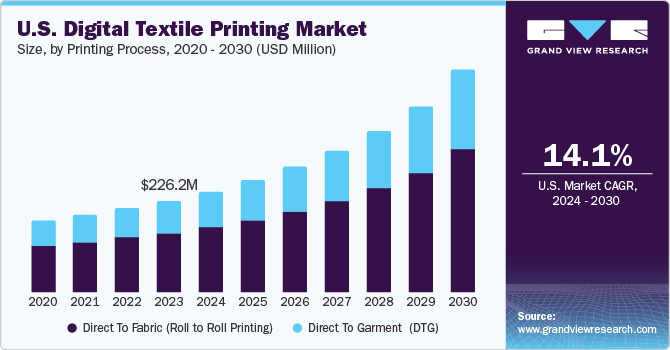

The U.S. digital textile printing market measurement was estimated at USD 226.2 million in 2023 and is projected to develop at a CAGR of 14.1% from 2024 to 2030. Digital textile printing gives higher precision than standard textile printing, which is among the many key elements fueling the market development. Attributable to its versatile nature, it finds utility in numerous sorts of textiles comparable to clothes, bedsheets, banners, sports activities attire, flags, car wrapping, and inside textiles, which in flip propels the market development. The expansion of the business may also be attributed to quickly altering style traits and the necessity for producers to rapidly adapt to these traits to remain related out there.

In 2023, the U.S. accounted for about 7.67% share of the international digital textile printing market. The digital textile printing business is at an evolving stage as in comparison with the standard textile printing business. Nonetheless, many utility sectors are quickly transitioning to digital textile printing, as a result of its excessive precision, effectivity, and flexibility. The speedy adoption of digitally printed design traits and the rise in disposable incomes are anticipated to propel the market development within the U.S. The elevated use of printed textiles in automobile inside décor and car wrapping is anticipated to propel the goal market.

Technological developments comparable to additive manufacturing for textile functions are anticipated to propel market development within the upcoming years. Digital textile printing helps in sooner turnaround occasions and excessive outputs, subsequently, producers can effectively make faster deliveries, meet prospects’ requests, and settle for extra tasks. Due to this fact, fast-fashion companies want it for sooner supply of prepared clothes and are therefore shifting to digital know-how for sooner turnarounds.

Digital textile printing requires superior equipment because it gives high-precision output. Nonetheless, the superior equipment prices are excessive and there’s an acute scarcity of expert manpower to function these superior machines. As well as, the fluctuating value of uncooked supplies comparable to ink and print heads, the dangerous results of inks, and the excessive prices of digital textile printers are anticipated to restrain market growth to a sure extent.

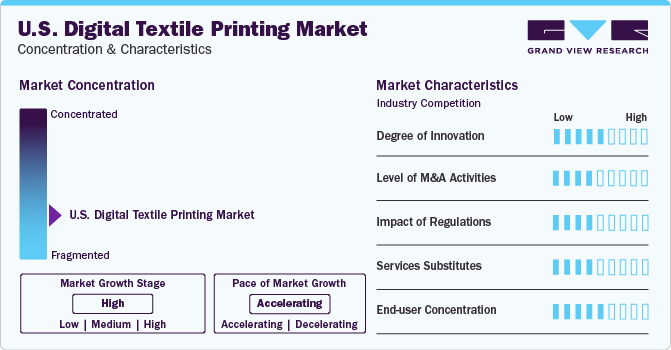

Market Focus & Traits

The stage of market development is excessive and the tempo of development is accelerating. The digital textile printing business within the U.S. is fragmented as there’s a presence of a number of massive and small firms out there. To acquire a aggressive edge and enhance their market share, suppliers of digital know-how are making vital investments of their R&D and interesting in M&A actions.

The appearance of 3D printing is considerably reworking the digital textile business because it permits the implementation of assorted shapes and buildings resulting in modern merchandise. There have additionally been improvements in textiles, comparable to in supplies and material compositions that embody good materials, conductive textiles, and sustainable blends, which improve aesthetics and performance. As well as, the digitization has streamlined all the textile manufacturing course of, which has enhanced the effectivity. Machine studying algorithms analyze huge quantities of information, optimizing manufacturing processes, predicting traits, and enhancing design choices. AI-driven insights drive effectivity and creativity.

The rules laid down by the Environmental Safety Company considerably influence the U.S. digital textile business. A few of the rules embody microfiber air pollution management, the textile business is urged to design materials that shed fewer microfibers and undertake manufacturing processes that reduce emissions, as microfibers shed throughout laundering contribute to water air pollution. Clear Water Act effluent restrict tips particularly for the textile business particularly regulate the discharge of pollution within the water our bodies. The EPA encourages the adoption of round practices within the textile business. This consists of material recycling, improved stock administration, and lengthening the life of clothes by restore incentives, style rental applications, and resale platforms. Such initiatives contribute to lowering greenhouse fuel emissions.

Printing Course of Perception

When it comes to the printing course of, the market is segmented into Direct to Cloth (Roll to roll) and Direct to Garment (DTG) segments. The Direct to Cloth (DTF) printing phase dominated the market in 2023 with the most important market share of greater than 67%. In DTF printing, designs and patterns are printed instantly on an enormous roll of material. DTF printing may be performed utilizing a broad vary of inks comparable to dye-sublimation inks, acid dyes, pigment inks, and reactive dyes. Firms present each sorts of printers because the demand for every kind is rising considerably.

The direct-to-garment phase registered the quickest CAGR of 14.4% over the forecast interval. The direct-to-garment technique entails the direct utility of designs onto clothes gadgets. The escalating demand for on-demand garment printing and the rising requirement for customized designs on t-shirts and shirts are propelling the necessity for direct-to-garment printing. Custom-made clothes are in excessive demand, particularly amongst sports activities golf equipment, colleges (for uniforms), and for company gifting. Digital printing is changing into more and more well-liked for customized attire as a result of its capacity to print any design on the material. Amongst numerous printing processes, direct-to-garment is rising as probably the most quickly increasing phase.

Operation Perception

Primarily based on operation phase, the market is split into two classes, single go and multi go segments. Single-pass printing is a more recent kind of digital textile printing that allows sooner printing at a better high quality. Single-pass printers obtain exceptional pace as a result of they disperse ink concurrently utilizing a number of printheads positioned over the substrate because it strikes by the printing course of. Regardless of the pace, single-pass printing maintains wonderful print high quality, making it best for mass manufacturing of assorted printed supplies. These benefits of single go printing have propelled the expansion of the phase and it’s anticipated to witness the quickest CAGR of 14.3% over the approaching years.

The multi go operation phase dominated the U.S. market in 2023 with the most important market share of over 61%. The massive share of the multi go printing is attributed to the benefits supplied by it such because it minimizes the preliminary prices required for printing know-how because it has a smaller variety of print heads. If a printhead malfunctions throughout multi-pass printing, subsequent passes can rectify any discrepancies within the print, thereby, leading to a better-quality print. Multi-pass printers are versatile and may deal with a wide range of totally different supplies, comparable to material, paper, or different substrates.

Ink Sort Perception

The sublimation phase dominated the U.S. market in 2023 with the most important market share of greater than 52%. This massive share is attributed to the rising demand for de-sublimation in personalized printing providers, which is among the many key elements for the phase development. Sublimation inks are extra sturdy than different ink sorts as they’re absorbed into the material quite than simply including a layer of coloration on the material. The sublimation phase can be anticipated to register the quickest CAGR over the projected interval. Artificial fibers comparable to polyester primarily use sublimation inks. This technique is environmentally pleasant as in comparison with different ink sorts because it doesn’t require washing of the textile after printing.

The reactive ink kind is predicted to be the second fastest-growing phase with a CAGR of 14.2% from 2024 to 2030. Reactive inks are primarily used for cotton as reactive inks produce high-quality and wealthy colours, particularly when printing on cotton or viscose materials. The printed colours stay intact even after a number of wash cycles. Reactive inks are versatile and can be utilized on numerous pure fibers, together with cotton, silk, wool, and viscose. Their flexibility permits textile printers to work with totally different material sorts, which in flip, drives the market development of this phase.

Acid inks are principally used on textile supplies that don’t simply retain the printed colours comparable to wool, and silk. Pigments and dispersed inks are used mostly within the standard textile printing. Nonetheless, in digital textile printing these ink sorts have the least utilization.

Software Perception

When it comes to utility, the U.S. digital textile printing business is segmented into clothes/attire, house décor, smooth signage, and industrial. Clothes/attire held the most important market share of greater than 52% in 2023. Digital textile printing has develop into a game-changer within the material attire business. Its benefits embody high-resolution prints, sooner sampling and supply, diminished material waste, environmental friendliness, and the flexibility to discover various designs. By embracing digital printing, companies can create personalized, visually interesting clothes whereas minimizing their ecological footprint.

Digital textile printing has reworked the panorama of sentimental signage. Digital printing delivers high-resolution graphics with vivid colours and complex particulars. Whether or not it’s occasion banners or retail shows, smooth signage advantages from eye-catching visuals that instantly seize consideration. Not like conventional strategies that contain display setups and minimal print runs, digital textile printing is cost-effective even for small portions. This flexibility caters to companies with various signage wants, permitting them to supply personalized smooth signage effectively. Cloth-based smooth signage is inherently light-weight and simple to move. Digital printing ensures that these textiles stay sturdy whereas sustaining their light-weight properties, making setup and relocation hassle-free. These benefits have led to the expansion of the phase and it’s anticipated to be the second quickest rising phase amongst functions.

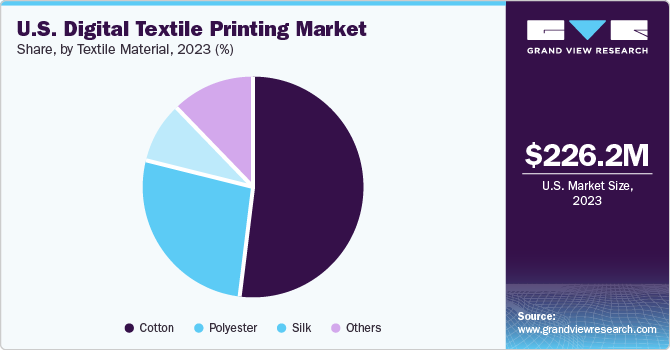

Textile Materials Perception

The cotton phase dominated the market in 2023 with the most important income share of greater than 52%. Cotton is extensively utilized in style and sportswear owing to properties of fantastic moisture absorption and prolonged sturdiness. Cotton has wonderful printability and sturdiness, which makes it an acceptable alternative for clothes, particularly style put on. Cotton can be most well-liked for numerous house décor textiles comparable to bedsheets, curtains, cushion covers, and desk covers owing to its softness, simple washability, and attractiveness. These elements are aiding the demand for printed cotton materials and clothes.

The polyester materials phase is anticipated to register the quickest CAGR of 15.0% over the forecast interval. This development may be attributed to numerous elements comparable to sublimation ink is predominantly utilized for substrates made from polyester material. As well as, as a result of its wrinkle and abrasion resistance, in addition to its affordability, polyester has develop into a well-liked alternative within the style business. These properties of polyester are driving the phase development.

Key U.S. Digital Textile Printing Firm Insights

A few of the key firms within the U.S. digital textile printing business are Mimaki Engineering, Epson America, and Kornit Digital, amongst others.

-

Mimaki USA Inc., a department of Mimaki Engineering, is famend for its big selection of digital textile printers, reducing plotters, latex, software program, and ending merchandise. With its most important workplace in Atlanta and a number of other different places throughout the USA, the corporate has a robust nationwide footprint. Mimaki has an intensive product line of over 50 gadgets, serving the signal graphics, textile & attire, industrial, and 3D markets. The corporate’s mission is to design smarter equipment that enhances buyer workflow and enterprise development. Mimaki USA Inc. is a worldwide supplier of modern options.

-

Epson America, an electronics producer, provides a broad vary of merchandise, together with printers, skilled imaging merchandise, projectors, scanners, system gadgets, and manufacturing unit automation merchandise. As a member of the worldwide Epson Group, it serves a wide range of sectors, together with sports activities, style, augmented actuality, and private healthcare. Along with its conventional choices, Epson America gives house leisure merchandise, glasses, health and sports activities merchandise, modules, kiosk merchandise, shows, disc publishers, provides, and equipment.

Roland DGA and Durst are a few of the rising firms within the U.S. digital textile printing business.

-

Roland DG Corp (Roland) is a producer and marketer of 3D milling machines, 3D printers, engraving machines, and desktop fabrication gadgets. The corporate’s product choices embody wide-format coloration inkjet printers, vinyl reducing machines, inkjet printers, inkjet cutters, 3D milling machines, engraving machines, 3D printers, dental 3D printers, dental milling machines, and picture influence printers for largescale signage and posters.

-

Durst Imaging Expertise US is a number one supplier of modern digital printing options, specializing in superior applied sciences for a variety of functions, together with textiles, signage, packaging, and industrial printing. As a subsidiary of the Durst Group, a worldwide chief in digital printing know-how, Durst Imaging Expertise US leverages many years of experience and a dedication to innovation to ship cutting-edge options tailor-made to the evolving wants of its prospects.

Key U.S. Digital Textile Printing Firms:

- Epson America

- Mimaki USA, Inc.

- Kornit Digital

- Roland DGA Company

- Dover Company

- Konica Minolta

- Brother Industries

- Colorjet

- Durst Picture Expertise US, LLC

- ROQ Worldwide

Current Developments

-

In January 2024, Epson unveiled a brand new addition to the SureColor F-Collection, a direct-to-garment (DTG) printer. This versatile, entry-level printer is engineered to cater to the wants of garment decorators, entrepreneurs, artisan companies, and print service suppliers, providing a wide range of DTG and direct-to-film (DTFilm) printing functions. The hybrid printer merges distinctive picture high quality, user-friendly operation, and adaptable efficiency in a compact bundle, releasing designers to focus extra on their artistic course of.

-

In March 2023, Mimaki USA, a producer of broad-format inkjet printers and cutters, launched its inaugural direct-to-film (DTF) printer, the “TxF150-75,” together with a warmth switch pigment ink, “PHT50,” particularly designed for DTF functions. The TxF150-75 is an inkjet printer able to producing DTF print switch sheets with a most width of 80 cm (31.5″). The newly developed PHT50 warmth switch pigment ink, appropriate for DTF functions, includes 5 colours (CMYK and white). It’s set to obtain the ECO PASSPORT certification by the top of March 2023, a vital requirement for complying with the worldwide security customary for textile merchandise, “OEKO-TEX.”

U.S. Digital Textile Printing Market Report Scope

|

Report Attribute |

Particulars |

|

Market measurement worth in 2024 |

USD 248.9 million |

|

Income forecast in 2030 |

USD 549.3 million |

|

Development charge |

CAGR of 14.1% from 2024 to 2030 |

|

Base 12 months for estimation |

2023 |

|

Historic information |

2017 – 2022 |

|

Forecast interval |

2024 – 2030 |

|

Quantitative models |

Income in USD million and CAGR from 2024 to 2030 |

|

Report protection |

Income forecast, firm rating, aggressive panorama, development elements, and traits |

|

Segments Lined |

Printing course of, textile materials, operation, ink kind, utility |

|

Nation scope |

U.S. |

|

Key firms profiled |

Epson America; Mimaki USA, Inc.; Kornit Digital; Roland DGA Company; Dover Company; Konica Minolta; Brother Industries; Colorjet: Durst Picture Expertise US, LLC; ROQ Worldwide |

|

Customization scope |

Free report customization (equal as much as 8 analysts working days) with buy. Addition or alteration to nation, regional & phase scope. |

|

Pricing and buy choices |

Avail personalized buy choices to satisfy your actual analysis wants. Discover buy choices |

U.S. Digital Textile Printing Market Report Segmentation

The report forecasts income development at a rustic stage and gives an evaluation of the newest traits and alternatives in every of the sub-segments from 2017 to 2030. For this research, Grand View Analysis has segmented the U.S. digital textile printing market report primarily based on printing course of, operation, textile materials, ink kind, and utility:

-

Printing Course of Outlook (Income, USD Million, 2017 – 2030)

-

Operation Outlook (Income, USD Million, 2017 – 2030)

-

Textile Materials Outlook (Income, USD Million, 2017 – 2030)

-

Cotton

-

Silk

-

Polyester

-

Others

-

-

Ink Sort Outlook (Income, USD Million, 2017 – 2030)

-

Sublimation

-

Pigment

-

Reactive

-

Acid

-

Others

-

-

Software Outlook (Income, USD Million, 2017 – 2030)

-

Clothes/Attire

-

Residence Décor

-

Delicate Signage

-

Industrial

-

Ceaselessly Requested Questions About This Report

b. The U.S. digital textile printing market measurement was estimated at USD 226.2 million in 2023 and is predicted to achieve USD 248.9 million in 2024.

b. The U.S. digital textile printing market is predicted to develop at a compound annual development charge of 14.1% from 2024 to 2030 to achieve USD 549.3 million by 2030.

b. The multi go phase dominated the U.S. digital textile printing market with a share of over 61.2% in 2023.

b. Some key gamers working within the U.S. digital textile printing market embody Epson America; Mimaki USA, Inc.; Kornit Digital; Roland DGA Company; Dover Company; Konica Minolta; Brother Industries; and Colorjet

b. Key elements driving the market development embody growing demand for personalized and on-demand printing options.